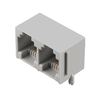

Exploring LINK-PP RJ45 Connectors in THT, SMT, and THR PCB Assembly Methods

1. Through-Hole Technology (THT) RJ45 Connectors

Overview:

Through-Hole Technology (THT) is one of the oldest and most reliable PCB assembly techniques. THT assembly involves placing component leads through drilled holes in the PCB and soldering them to the copper traces on the opposite side. LINK-PP offers a variety of THT RJ45 connectors designed to endure mechanical stresses and ensure a strong physical connection to the PCB.

Key Features:

- Durability: THT RJ45 connectors offer exceptional mechanical strength due to the physical anchor provided by the through-hole leads. This makes them ideal for applications where the connector might be exposed to mechanical stress, such as frequent plugging and unplugging.

- High Current Capacity: THT connectors can handle higher currents than SMT, which makes them suitable for power-intensive devices.

- Hand or Automated Assembly: Though THT can be soldered manually, it can also be done using wave soldering for higher-volume production.

Applications:

- Industrial and Automotive Systems: THT RJ45 connectors are often found in systems where the mechanical stability of the connector is critical due to harsh environmental conditions.

- High-Vibration Environments: The mechanical bond of THT RJ45 connectors ensures they hold up well in applications prone to vibrations, such as industrial equipment and vehicles.

Advantages:

- Mechanical robustness for high-stress applications.

- Suitable for wave soldering, simplifying mass production.

Considerations:

- THT assembly can be more time-consuming, and because it requires drilled holes, it limits PCB routing flexibility and is not ideal for compact designs.

2. Surface Mount Technology (SMT) RJ45 Connectors

Overview:

Surface Mount Technology (SMT) is the preferred method for high-speed automated PCB assembly. In SMT, RJ45 connectors are soldered directly to the surface of the PCB without requiring holes, which allows for higher component density, more compact PCBs, and more efficient manufacturin

Key Features:

- Compact Design: SMT RJ45 connectors are designed to occupy minimal space on the PCB, making them ideal for compact devices where PCB real estate is at a premium.

- Efficient Mass Production: SMT is compatible with automated pick-and-place machines, reducing assembly time and cost. The process involves applying solder paste to the PCB pads, placing the RJ45 connector, and reflowing the solder in an oven to secure the connection.

- High-Frequency Performance: SMT connectors typically have lower parasitic inductance, resulting in better signal integrity and performance for high-speed data transmission.

Applications:

- Consumer Electronics: Devices such as routers, modems, and smart home devices often use SMT RJ45 connectors due to their compact size and efficient production.

- IoT and Networking: With the need for miniaturized yet high-speed networking components, SMT RJ45 connectors are common in IoT gateways, switches, and other networking infrastructure.

Advantages:

- Compact and lightweight, supporting modern miniaturized designs.

- Automated assembly, lowering production costs and increasing efficiency.

Considerations:

- Less mechanically durable compared to THT, especially under stress or in high-vibration environments, unless extra physical support is provided on the PCB.

3. Through-Hole Reflow (THR) RJ45 Connectors

Overview:

Through-Hole Reflow (THR) combines the mechanical benefits of THT with the manufacturing efficiency of SMT. In this method, the RJ45 connector is inserted into pre-drilled holes (like THT), but instead of using wave soldering, the assembly undergoes a reflow process like SMT. This allows the use of both through-hole and surface-mount components in the same automated process.

Key Features:

- Mechanical Stability: Like THT, THR provides a robust mechanical connection by anchoring the RJ45 connector through the PCB holes.

- Automated Reflow: THR connectors are compatible with the same automated reflow soldering processes used for SMT, enabling high-volume production while maintaining the mechanical advantages of through-hole mounting.

- High Efficiency: THR eliminates the need for separate wave soldering processes for through-hole components, streamlining production by allowing mixed-technology boards (both SMT and THR) to be completed in a single pass through the reflow oven.

Applications:

- Telecommunications Equipment: THR RJ45 connectors are used in high-density telecom and data communication systems where reliability and automated assembly are key.

- Automotive Electronics: THR connectors offer the mechanical robustness needed in automotive applications while still benefiting from automated assembly processes.

Advantages:

- Combines the mechanical strength of THT with the automated efficiency of SMT.

- No need for additional wave soldering, simplifying the assembly process for mixed boards.

Considerations:

- THR requires reflow-capable soldering processes and ovens, making it best suited for large-scale, high-volume production lines.

Key Features of LPJG0926HENLS4R PoE+ RJ45 Connector

Superior Housing Material:

The thermoplastic PA46+30%G.F material used in the housing has a high melting point and low humidity absorption, ensuring reliable operation in extreme environments. This makes it ideal for industrial automation, where temperature variations and humidity can affect performance.

Optimized for Reflow Soldering:

With a maximum reflow temperature of 260°C for up to 10 seconds, the LPJG0926HENLS4R delivers optimal soldering performance. The precision in reflow temperature ensures secure and stable solder joints, reducing the risk of component failure during operation.

Stand-Off Height for Airflow and Soldering:

The stand-off height between the component and the PCB facilitates better airflow and solder paste distribution, enhancing cooling and ensuring the solder paste flows properly. This spacing is crucial in high-speed networking equipment, where thermal management and precise soldering are essential.

Pin Length for Optimal Soldering:

The pins extend 2.40mm from the PCB surface, ensuring thorough contact with the solder paste and improving the effectiveness of the reflow process. This design ensures that all pins are soldered correctly, even in complex, high-density boards.

Avoiding Common Soldering Issues:

LPJG0926HENLS4R is designed to eliminate a common soldering issue: in many components, soldering points more than 1 mm away from the outer edge often don’t receive enough heat to melt the solder paste. LINK-PP’s innovative design ensures the solder paste melts completely, resulting in secure and reliable joints throughout the component.

High-Viscosity Solder Paste:

LINK-PP utilizes high-viscosity solder paste for THR soldering applications, providing a more consistent and reliable bond, improving the component’s mechanical stability, and ensuring the LPJG0926HENLS4R maintains secure connections over time.

Conclusion: LPJG0926HENLS4R—A Game Changer with THR Technology

The LINK-PP LPJG0926HENLS4R PoE+ RJ45 connector offers an impressive combination of high-performance materials, optimized reflow soldering, and mechanical stability through THR technology. Its ability to meet the demands of networking, communication, and industrial automation applications—while reducing production and maintenance costs—makes it a standout choice for engineers and manufacturers alike.

By leveraging THR technology, LINK-PP continues to innovate and improve the way electronic components are integrated, helping companies lower operational expenses and boost production efficiency in increasingly competitive markets. For any project requiring reliable and high-performing Ethernet connectivity, the LPJG0926HENLS4R is a strong, cost-effective solution.

Choosing the Right Assembly Method for LINK-PP RJ45 Connectors

When it comes to RJ45 connectors, the choice between THT, SMT, and THR assembly methods depends largely on the specific requirements of your design:

- THT RJ45 connectors are perfect for rugged, high-stress environments where mechanical durability is crucial.

- SMT RJ45 connectors are ideal for compact, high-volume applications where space, speed, and efficiency are key.

- THR RJ45 connectors offer a hybrid solution that combines the mechanical benefits of THT with the efficiency of SMT, making them ideal for applications that require both strength and mass-production efficiency.

LINK-PP’s RJ45 connectors are designed to meet the diverse needs of modern electronics, ensuring high performance, reliability, and flexibility in any assembly process. Understanding these assembly methods allows engineers to select the best-fit solution for their specific project, ensuring the highest levels of performance and efficiency in Ethernet-enabled devices.